Profile points are points on a bottom hole assembly (BHA) that define its (directional) drilling behavior and that form an integral part of the BHA. Examples of such points are stabilizers, motor bends, bit gauge lengths etc. The combination of all profile points (defined as dimension and distance from the bit) form the “fingerprint” of a BHA. This "fingerprint" is encoded into the database when the BHA tally is calculated and can be used to search the database for BHA’s with specific characteristics (i.e. a motor bend, stabilizer sizes at specific distance range from the bit, etc.).

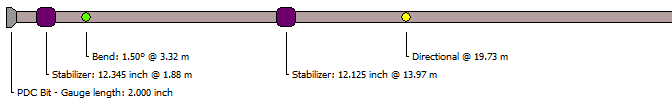

In addition to profile points that influence the BHA behavior, MWD and LWD sensors may also be specified as profile points. This is done for the purpose of showing bit to sensor distances in the BHA schematics. An example of a BHA schematic is shown below. It may optionally be printed on BHA reports.

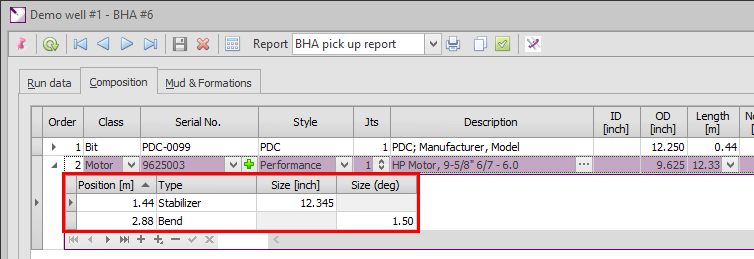

All profile points are entered in a sub-grid of the tool record they are part of.

The actual placement (Position) of the profile point is given as the distance relative to the bottom connection shoulder of the tool. For stabilizers and alike this should always be measured to the center of the blade (see below). The secondary dimension, where applicable, depends on the tool and profile point type (i.e. inches/millimeter for a stabilizer gauge, degrees for a bend angle, etc.). The dimension cell that is not applicable (i.e. degrees for a stabilizer) is not accessible.

Some MWD systems consist of a special sub with a non-magnetic drill collar below it. The MWD tool is then hung off in the sub so that the sensor package sits inside the non-magnetic drill collar. In this scenario the sub should have tool class 'MWD' and the non-magnetic drill collar should have tool class 'DC' (there should only be one tool class MWD in the tally). To ensure correct calculation of the bit-sensor distances, the sensor profile points (belonging to the sub with tool class 'MWD') should be entered as a negative value to indicate that they are positioned below the sub.

Some MWD systems consist of a special sub with a non-magnetic drill collar below it. The MWD tool is then hung off in the sub so that the sensor package sits inside the non-magnetic drill collar. In this scenario the sub should have tool class 'MWD' and the non-magnetic drill collar should have tool class 'DC' (there should only be one tool class MWD in the tally). To ensure correct calculation of the bit-sensor distances, the sensor profile points (belonging to the sub with tool class 'MWD') should be entered as a negative value to indicate that they are positioned below the sub.

To avoid repetitive input, tool records and profile points are best input in the Equipment Inventory on the well form. When tools are copied into a BHA tally (by selecting a serial number from the drop-down list, copying a previous tally or by drag & drop, all profile points are copied along with the tool record. Note that profile points are copied and data may be adjusted afterwards. For example if a motor is listed in the inventory with a 0.75° bend and 12 1/8" stabilizer sleeve, these values may be overruled for individual BHA's by simply adjusting the bend or stabilizer profile point.

To avoid repetitive input, tool records and profile points are best input in the Equipment Inventory on the well form. When tools are copied into a BHA tally (by selecting a serial number from the drop-down list, copying a previous tally or by drag & drop, all profile points are copied along with the tool record. Note that profile points are copied and data may be adjusted afterwards. For example if a motor is listed in the inventory with a 0.75° bend and 12 1/8" stabilizer sleeve, these values may be overruled for individual BHA's by simply adjusting the bend or stabilizer profile point.

|

Copyright © 2023 Softdrill NL |